Factories run really hot. Add acids that eat through metal, pressures that crush regular materials, and vibrations that shake equipment apart, and it’s a wonder anything survives at all. But today’s industrial gear lasts longer than the stuff from twenty years ago. And it uses way less energy doing the same job.

Materials Built for War Zones

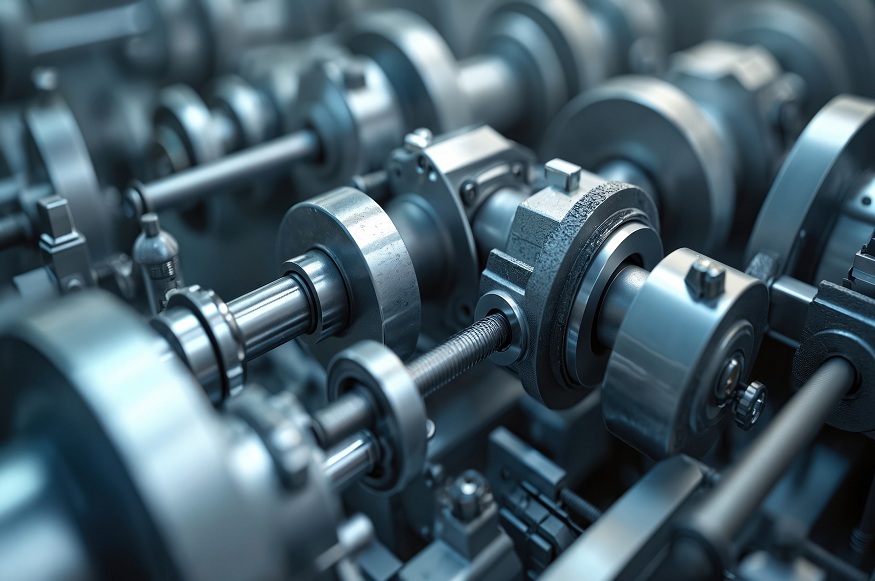

Industrial equipment goes through absolute torture. Furnace walls see temperatures that turn rock into lava. Chemical tanks hold stuff that would burn through your car like butter. These parts can’t just survive a few months. They need years of life. Ceramics stepped up big time. Forget your coffee mug; industrial ceramics handle heat that makes steel puddle on the floor. They barely expand when heated, so no cracking. Turbine blades coated with ceramic run scary hot. Why care? Hot engines burn fuel better. Simple as that.

Composite materials get interesting. Mix glass fibers with plastic, add some carbon threads, maybe throw in phenolic prepregs for heat resistance. The team at Axiom Materials explain that suddenly you have something light as aluminum but tough as steel. Mother Nature never cooked up anything this good. Engineers did.

Then there’s nano-coatings. Spread a layer thinner than dust on metal parts. That invisible shield fights off rust, chemicals, and wear like you wouldn’t believe. One tiny coating doubles how long a part lasts.

Machines That Tattletale

Old-school maintenance went like this: run it till it breaks, fix it, repeat. Today’s machines rat themselves out before breaking down. They have sensors everywhere. They feel vibrations, check temperatures, measure pressure. A bearing wearing out shakes just a tiny bit differently. Most people wouldn’t notice. But software catches it weeks early. Fix it on your schedule, not when it explodes during a production run.

Computers now learn what each machine sounds and feels like when healthy. The slightest weird reading sets off alarms. No more crossing fingers and hoping things hold together until the weekend. Engineers in one state fix problems in another without traveling. Cameras and sensors let them see everything remotely. Machine acts up in Maine? An expert in California logs in and figures it out. Plane tickets saved, problem solved faster.

The Energy Game

Industrial plants are energy hogs. Cut their appetite just a bit, and you save ridiculous amounts of money. So engineers got creative. Motors used to go at full speed or nothing. Variable-speed drives solved that problem. Now motors speed up or slow down based on what’s actually needed. Moving half the material doesn’t take half the power; it takes way less. Thank physics for that gift.

Waste heat became the new gold mine. All that hot air leaving smokestacks? That’s money floating away. Smart facilities catch it. They use hot exhaust from Process A to warm up Process B. Steam that would have vanished now spins generators. Insulation got a serious upgrade too. Forget that pink itchy stuff in your attic. New vacuum panels insulate ten times better in the same space. Aerogels (basically solid smoke) stop heat cold. Keeping heat where you want it slashes fuel bills hard.

Conclusion

Industrial facilities keep getting tougher and smarter. New materials shrug off conditions that destroy old equipment. Computers catch problems before they happen. Energy that used to vanish now does useful work. Labs pump out new materials monthly. Artificial intelligence gets scarier good at predictions. Recovery systems grab waste from places nobody thought to look before. Tomorrow’s factories won’t look much like today’s. They’ll break down less, produce more, and sip energy instead of gulping it. Good for business, good for workers, good for everyone who buys what factories make.